In the project processing at Ursa-Chemie, laboratory tests are carried out on all inquiries based on the customer’s manufacturing documents. It is always a matter of transferring the customer’s specified manufacturing procedure to Ursa-Chemie’s production vacilities. Simulating the production conditions in the “real” reactors in the laboratory requires a lot of experience and manual skills on the one hand and the right technical equipment on the other. While simpler mixtures and syntheses are performed in classic laboratory equipment, more complex products require a little more “technology”.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

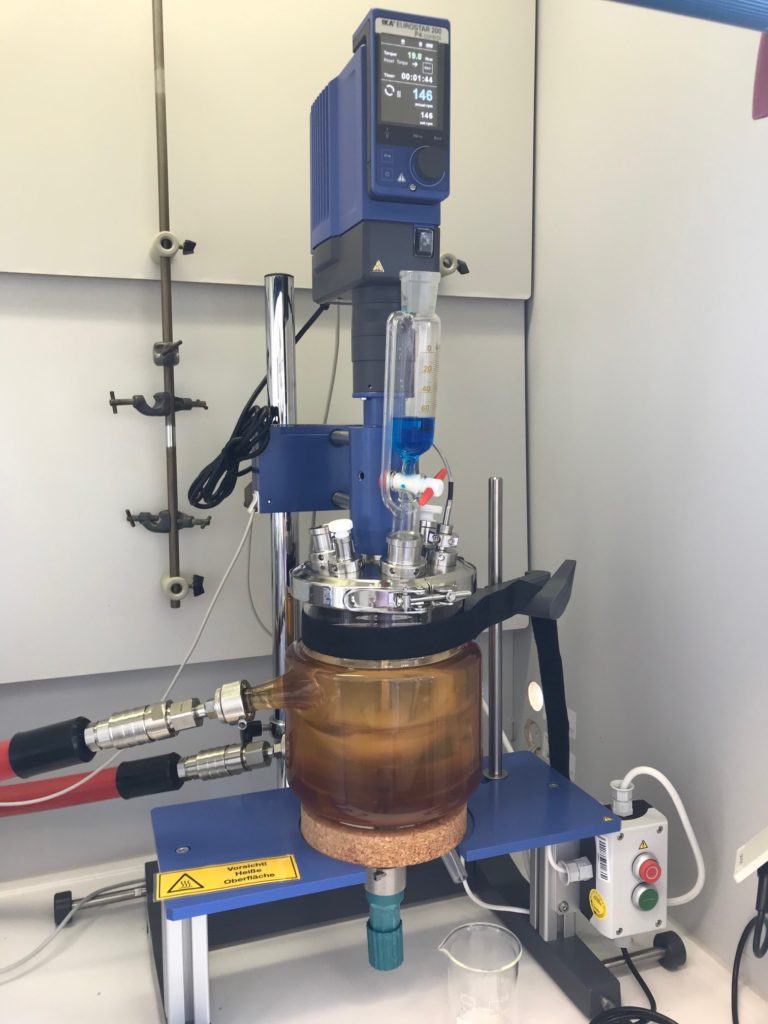

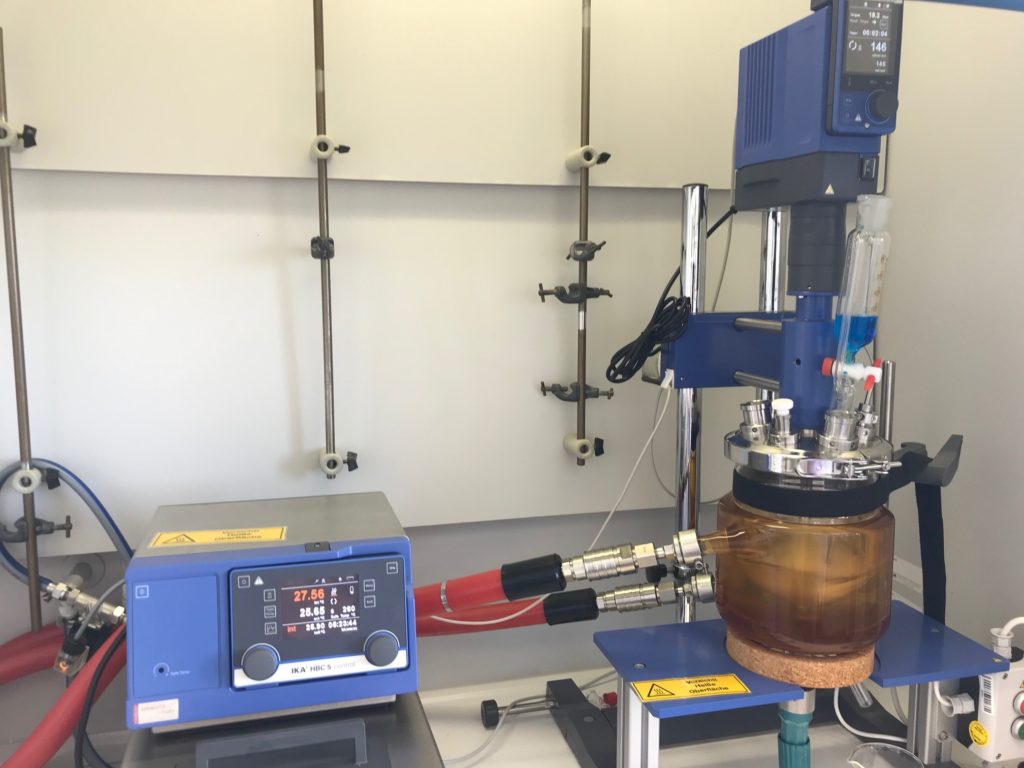

More InformationThe use of our laboratory reactor allows us to work at temperatures up to 230 °C and to stir products up to viscosities of 200,000 mPas on a scale of 2 liters. Various interfaces on the device allow the digital recording of process data – as in the “real” production. The recorded laboratory data serve as the basis for the assessment of the feasibility by our “technicians” in their vessels. For example, the development of temperature and / or viscosity over time is recorded and analysed for any “peaks”.

The 2 L glass reactor is heated or cooled by a double jacket and simulates the inertia of the technical system much more realistically than working with a heating mantle or an oil bath. The filling of the products takes place (as in the production) through a bottom valve, whereby filling times can be determined. Last but not least, the subject of “system cleaning after production” is also directly present in the laboratory development.